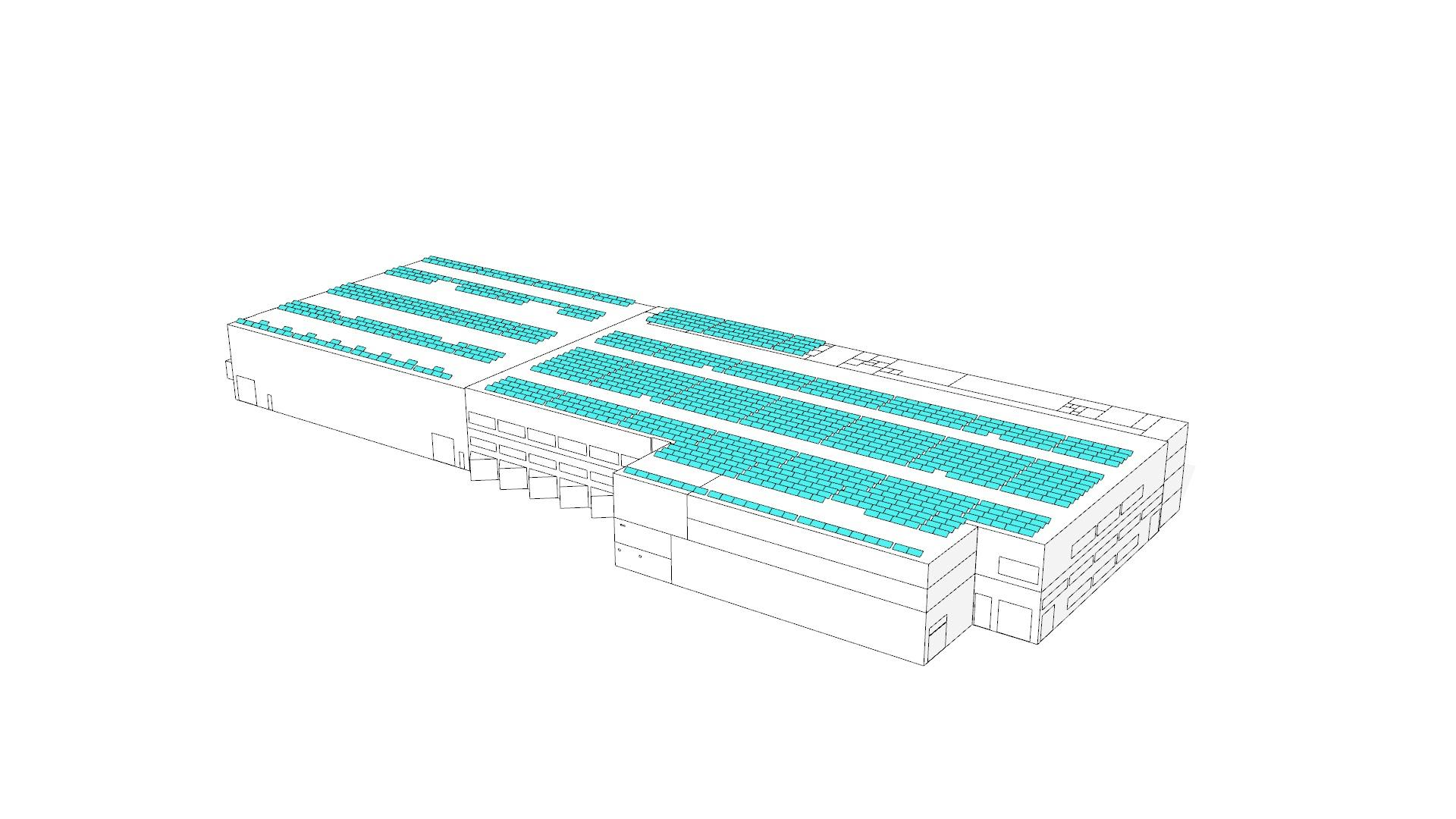

Sustainableextensionofamanufacturinghall

Kecskemét, Hungary

Typology

IndustrialSize

17 000 m2 GFAValue

21.5 million EURStatus

Under ConstructionOur Involvement

Sustainability Consultancy (DGNB)Equinox Team

Bálint Bakos, Balázs Fürtön, Dóra SzagriClient

HILTIThe project involves an extension to HILTI’s existing factory in Kecskemét, Hungary, creating 73 new jobs - the endeavour is mutually financed by HILTI and the Hungarian government.

As part of Liechtenstein-based HILTI’s commitment to sustainability, the scheme has gone through DGNB certification. The DGNB system is based on a holistic understanding of sustainability that takes into account the environment, people and economic efficiency in equal measure. It is internationally regarded as a well-versed framework for sustainable design and is applied worldwide. More than 10,000 projects in around 30 countries have already been awarded by the DGNB.

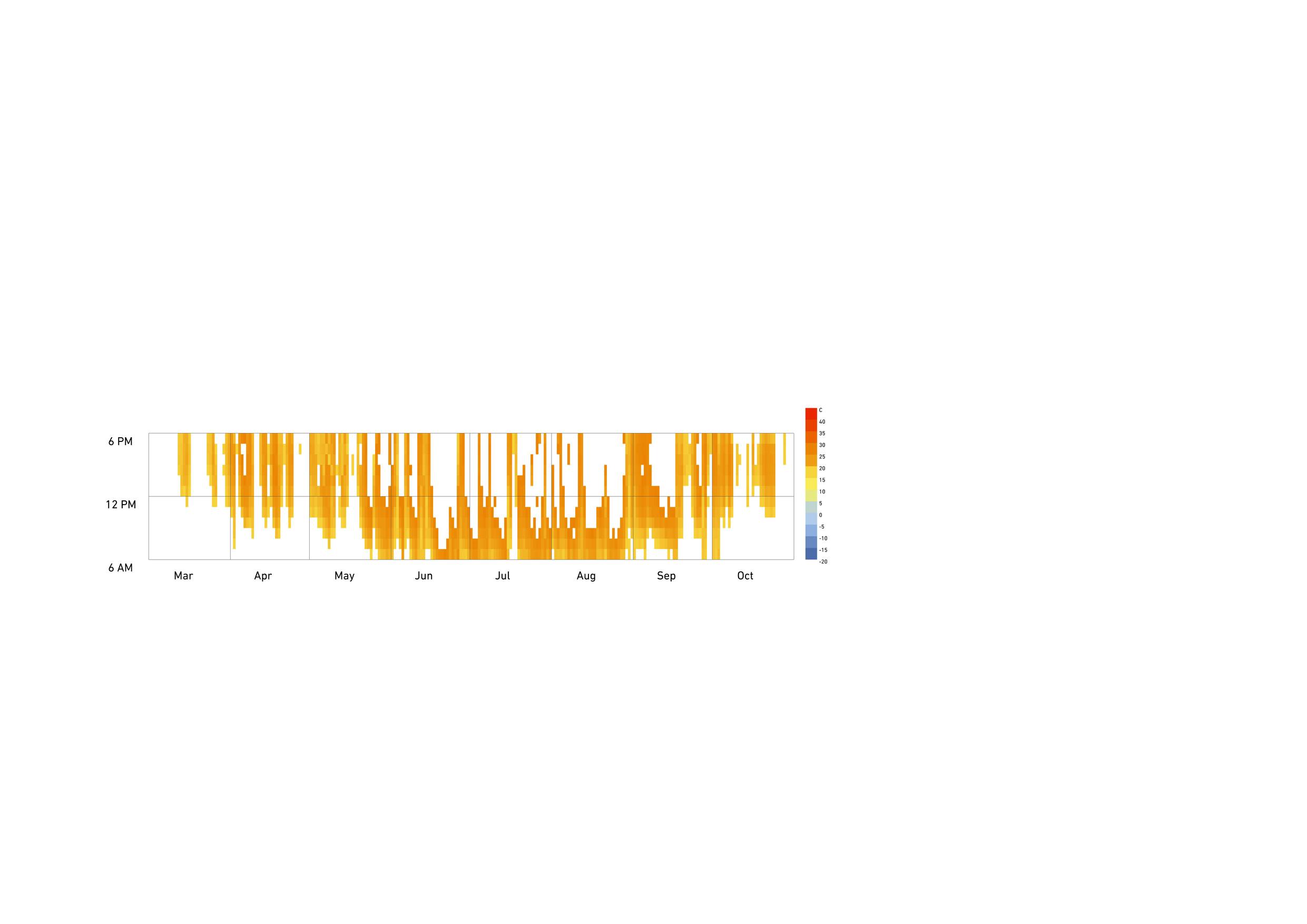

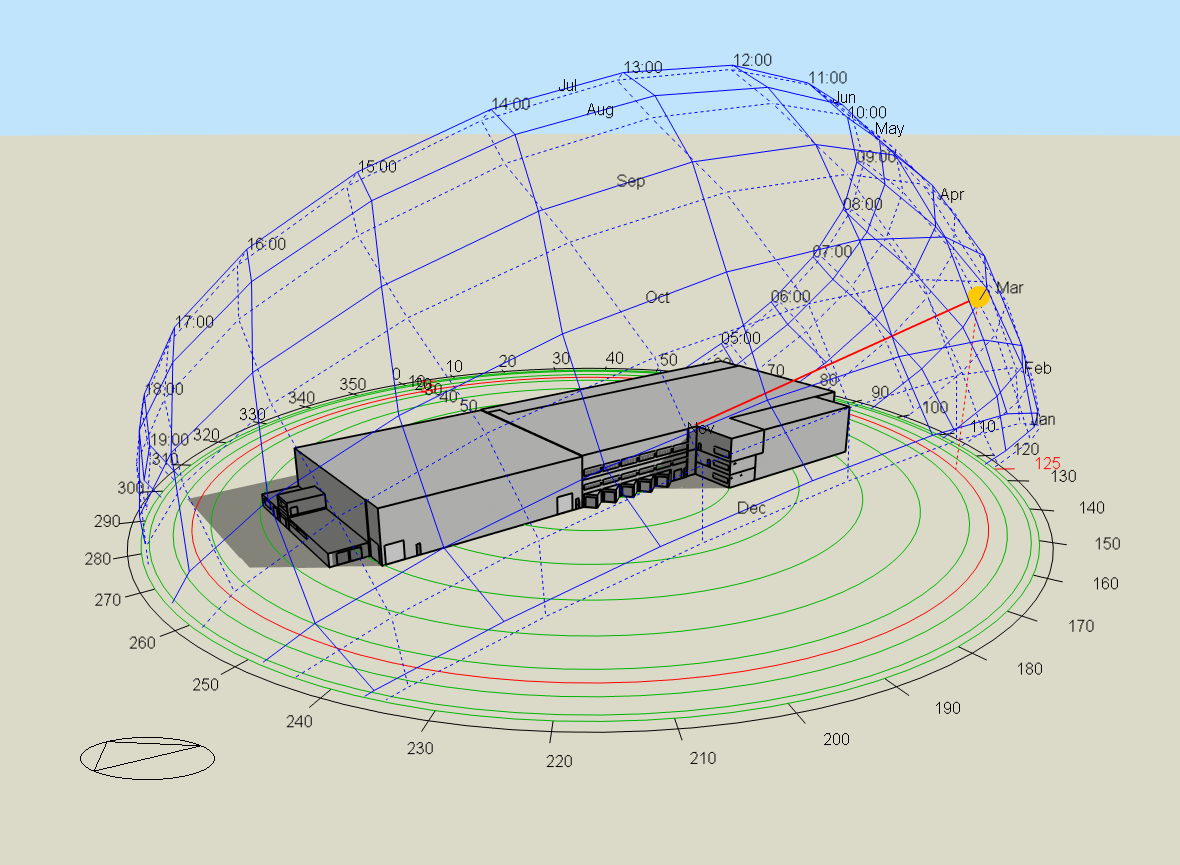

Equinox was involved as an expert supporting two DGNB chapters with consecutive analysis: SOC 1.1 Thermal comfort and ENV 1.1 Building life cycle assessment.

SOC 1.1 Thermal comfort involves detailed energy modelling using DesignBuilder and EnergyPlus, to guarantee thermal comfort that is appropriate for the intended use of the building throughout the year regardless of season, and to ensure user comfort.

ENV 1.1 Building life cycle assessment’s objective is to ensure a consistent life cycle approach to the planning of buildings in order to reduce emissions related impacts on the environment and consumption of non-renewable resources to a minimum across all stages in the life of a building.